Control panels & control systems are a specialized discipline, especially when

modern, automated systems must interact with complex cues from the work

environment.

- Specialist knowledge on industrial projects for material selection and procurement related to electrical & instrumentation.

- Ability to pre-fabricate instrument support & other fabrication work for control packages on or off site.

- Communication networks such as Device net / Profibus / S Bus / Control net / RS485 / Ethernet TCP I/P are some to be mentioned that we worked

up on to communicate the field I/O and devices to interlink with the controller. - Plant process control in view of the zones and safety of the area

Instrumentation

We offer following instrumentation services:

- Supply & Installation of Transmitters, Switches & Gauges for Pressure, Temperature Flow and Level application, Control Valves, on / off valves,

Breather valves, Safety Valves, panels, junction boxes, cable laying & termination, perforated cable tray work, pedestal fabrication. - Supply & Installation of DCS and PLC systems, SCADA systems, hazardous area control systems, fire and gas systems and process installation,

termination & commissioning of indicators, transmitters and controllers, valves & other field instruments. - Supply & Installation including cabling, marshalling panels, instrument air/gas tubing and impulse piping work.

- Testing, calibration & loop checking through fully trained technicians with certified testing equipment.

- Intrinsically safe barriers for highly sensitive environmental applications

- State of the art programming and communication networks by our specialised control engineers will commission a system as a mark of standards.

CONTROL PANEL ENGINEERING IS OUR BUSINESS

- We Provide total controls engineering design which includes

- Complete Engineering Designs which includes

- Panels Design (Auto cad / E plan)

- Electrical Switchgear selections

- Control Logic flow chart as per Philosophy and Cause and Effect of the Project

(Prior approvals) - SCADA / HMI Design (Prior approvals)

- Product selection as per Client PVL

- Field Layouts

- Field instrumentation selection and approvals

- Cable tray routing and sizing.

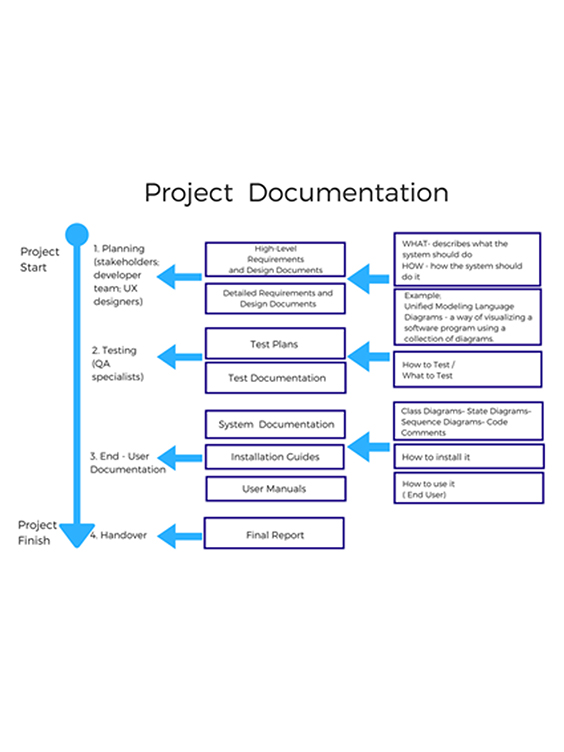

CONTROL PANEL

Control Panel Design our Areas of Specialization Include:

- Process & Machine Control Panels and Systems

- Applications Consulting & Systems Design

- Drive/Motion Control/PLC Control Panels and Systems

- Local Control Panel.

- Local Operating Panel.

- Machine Monitoring System.

- Purge & Pressurization Panel.

- Flameproof Control Panel.

- Pneumatic & Hydraulic Control Panels and Systems

- Complete Systems Documentation

- Testing to Client Specifications

- Field Support by Skilled Engineers

- Panel Design & Fabrication to NEPA79 Standards.

CONTROL PANEL ENGINEERING IS OUR BUSINESS

- We Provide total controls engineering design which includes

- Complete Engineering Designs which includes

- Panels Design (Auto cad / E plan)

- Electrical Switchgear selections

- Control Logic flow chart as per Philosophy and Cause and Effect of the Project

(Prior approvals) - SCADA / HMI Design (Prior approvals)

- Product selection as per Client PVL

- Field Layouts

- Field instrumentation selection and approvals

- Cable tray routing and sizing.

Instrumentation & Automation Control

Site Installations

“Our goal for every customer is a trouble-free startup at their facility”

- Supervision

- Installations

- Cable Trays & Ladders

- Cable Laying’s & Terminations

- Panels

- Sensors & Field Devices

- Inspections

- Permits & Approvals

- Energisations

- Tie-in’s

- Testing’s

- Commissioning’s

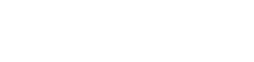

Engineering Documentations

In Engineering Projects handling of the project will be reflected by how the project is documented and handled at each and

every stages of the project, We submit each and every procedure as per the project specifications and Design basis, we submit below mentioned documentations for our projects, apart from other specified procedures as required.

- Inspection and Test Protocols (ITP’s)

- Document registers

- Materials Submittals

- Engineering Design approvals

- FAT & SAT Procedures

- Pre Commissioning & Commissioning Procedures

- Performance Test Procedures

- SPIR’s